OEM in EAST INDIA in FIBER LASERS

OEM in EAST INDIA in FIBER LASERS

OEM in EAST INDIA in FIBER LASERS

OEM in EAST INDIA in FIBER LASERS

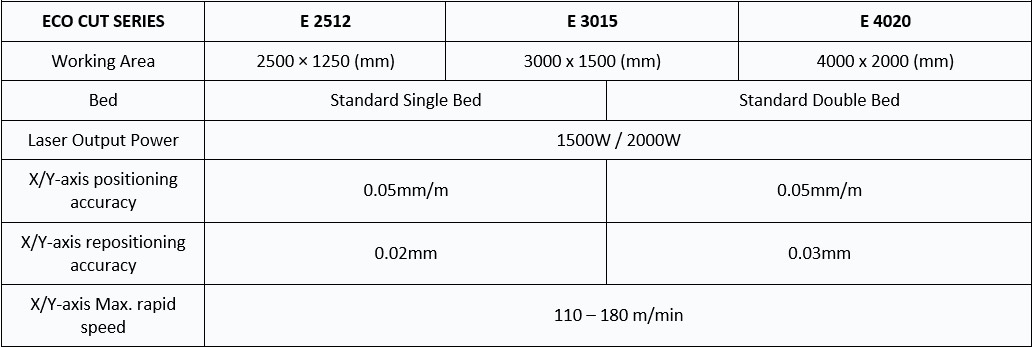

ECO-CUT. An ideal entry-level flatbed Laser Cutting Machines, doesn't need high budget to fulfil your complete requirement. ECO-CUT has a perfect mechanical property with highly Strong Machine Bed with 2 stage stress relieving with high compressive strength and hardness that last up to 30 years without any distortion Equipped with 1500 - 2000 Watt laser source and working area of 2500mm x 1250mm | 3000mm x 1500mm and 4000mm x 2000mm to meet different cutting needs. The Eco Cut Fiber laser cutting machine achieve rapid traverse speeds up to 110-150m/min and acceleration of nearly 1.0 – 1.5G, it guarantees the best quality, precision and cutting efficiency at low cost.

The complete bed frame is fabricated with tubular section & is stress relieved using vibratory & heat treatment. This methods takes hours & even days where the bed sizes are larger. By doing so the molecules in the steel bed achieves nearly 70% even distribution within them and ensure high precision cutting over prolonged usage.

The gallant make 1st Generation Carbon Steel gantry has high tensile strength with high stiffness and durability. It minimizes deformation caused due to environmental changes and maintains optimum part accuracy over the full cutting area by minimising friction & Saves nearly 30 % Time & Over all machine cost when compared to other OEMs

We have developed modular design over the years for our laser machine which ensure the machine is available in various form factor as per the customer’s requirement. Available in single & double table along with options to get integrated control panel to save floor space.

WEIHONG NC studio NK260 NK280 software NC studio V10 3 axis integrated CNC system

The NC Studio system is the most reliable and cost-effective motion control system for the entry level CNC Laser Cutting Machines. The system supports G codes, PLT code formats generated by various CAD / CAM software such as UG, MASTERCAM, CASMATE, Art CAM & AUTOCAD format. It is based on the Microsoft Windows operating system, giving full play to the powerful advantages of 64-bit computing and multitasking. The user interface of the NC Studio system is simple, reliable and easy to learn. This system not only has the functions of manual, stepping, automatic and mechanical origin return but also has unique functions such as simulation, dynamic display tracking & Z-axis automatic tool setting. This is a cost effective system with high reliability and stability making it an ideal choice for our entry level ECO CUT Machines.